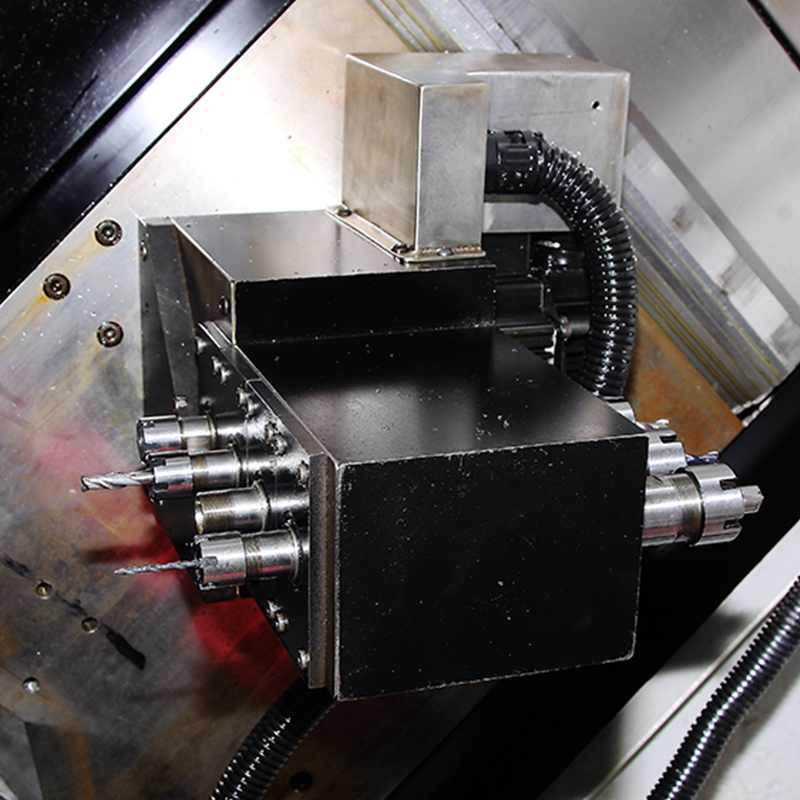

The power head is the power component of the CNC combination lathe, that is, the CNC turn-milling composite machine. The excellent performance of the power head is directly related to the machining performance of the turning and milling composite machine. The manufacturer of turning and milling complex machine must consider the coordination between the power head and the machine parameters when developing the power head. In addition, we also need to learn the skills of using the power head correctly to maintain the long-term operation of the power head of the turning and milling compound machine. The following details the correct use of the power head of the milling compound machine.

First of all, in order to ensure the long service life of the internal oil seal of the power head, when the coolant of the servo power head is not opened, the power head must not be used directly, because if the coolant is used without starting, it will increase the wear of the internal oil seal, and the speed is very fast. It will cause great harm to the oil seal, and then directly reduce its service life.

Second, in order to ensure that the power head of the CNC lathe is in use, it greatly reduces the wear and damage of small accessories in its power tool holder, as well as the wear of its oil seal, so that we not only need to start the coolant of the power head first, and then proceed to the next step; Secondly, we also need to provide suitable filtration equipment for its coolant to filter and maintain these coolants, so that while ensuring the purity of the coolant, it can ensure the service life of the internal parts of the tool holder and the oil seal, and accept very small wear damage.

Third, when using the power head of the CNC lathe, it is also necessary to pay close attention to the running speed of its tool holder, because each object or part has its own different additional speed, and the tool holder is the same, so it is necessary to ensure that the faster rolling speed of the tool holder is between its additional speed scale, so as to effectively avoid the wear of the tool holder.

Fourth, equal to the additional speed of the power head tool seat, the tool seat also has a certain demand, so it is necessary to ensure that its working environment does not exceed its limit.

After learning the above skills, in order to correctly use the CNC lathe turning and milling machine for production, in order to ensure the quality of the workpiece, as much as possible to reduce the damage to the power head.

Tel: 0757-88583990

Email: 574803257@qq.com

Add: No.5 Xingwang Road, Lianxing Wangbian Industrial Zone, Luo Village, Shishan Town, Nanhai District, Foshan City