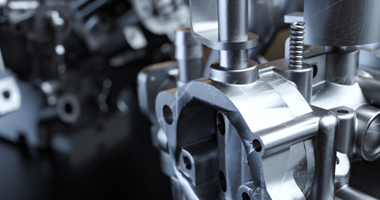

As we all know, CNC machining is suitable for complex processing, multi-process, high requirements and high demand, various types of ordinary lathes and various fixtures, as well as parts that need to be clamped and adjusted several times. Its processing objects are mainly box parts, complex surfaces, special-shaped parts, composite plate parts and CNC machining.

Sports equipment accessories processing

(1) box parts

Box parts generally refer to parts with a porous system, an inner cavity, and a certain length, width, and high proportion. Such parts are mainly used in lathes, automobiles, aircraft manufacturing and other industries. Box parts generally require multi-station holes and surface processing, and high tolerances are required, especially the tolerances of shape and position are relatively strict. They usually go through milling, drilling, reaming, reaming, spot welding, tapping and other processes that require more tools. Used for processing box parts in processing. When there are multiple processing stations and can only process parts, generally choose boring and milling processing.

(2) Complex surfaces

Complex surfaces play a very important role in machinery manufacturing, especially in the aerospace industry. Using ordinary machining methods, it is difficult or even impossible to complete complex surfaces. In China, the traditional casting method is accurate casting, and it can be imagined that its accuracy is low. Complex curved parts.

(3) special-shaped parts

Special-shaped parts are irregular parts, most of which require multi-station machining of points, lines and surfaces. The stiffness of special-shaped parts is generally poor, the clamping deformation is difficult to control, the processing accuracy is difficult to ensure, and even some parts of some parts are difficult to complete with ordinary machine tools. With processing hours, reasonable process measures should be taken to clamp once or twice, and the processing characteristics in the processing are mixed with multiple stations, which can complete multiple or all processes

(4) Discs, sleeves and plates

For disk parts with keyways or radial holes or distributed hole systems, bent disk sleeves or shaft zeros, such as flange bushings, keyways or square shaft parts and porous machining plates, should be selected in vertical machining, such as various motor end faces with distributed holes and bent disk parts should be selected in horizontal machining with radial holes.

Tel: 0757-88583990

Email: 574803257@qq.com

Add: No.5 Xingwang Road, Lianxing Wangbian Industrial Zone, Luo Village, Shishan Town, Nanhai District, Foshan City