The way to solve the rust of the guide rail is either to change the water-based cutting fluid to oil-based cutting oil, emulsified oil, or to replace the cutting fluid with a cleaning effect that is not particularly good, or to choose the lubricating oil containing molybdenum as an anti-wear raw material.

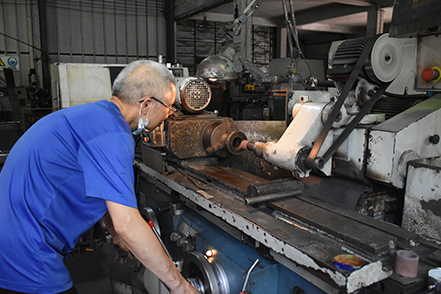

Experienced CNC lathes and processing operators must have encountered: the use of anti-rust cutting fluid in daily production should have a very good anti-rust effect, and the anti-rust cycle of processed products between processes can also achieve the desired effect, but the production equipment CNC lathes, processing tables and guide rails often rust.

Since the anti-rust performance of the cutting fluid is very good, why will the production equipment rust? Is there a relationship between the cycle and the cutting fluid? What kind of relationship is that?

The anti-rust performance of the workpiece after processing is still acceptable, so the poor anti-rust performance of the cutting fluid can be basically excluded, and the guide rail corrosion directly caused by the cutting fluid can also be excluded.

It's down to the rail door smeared with rail oil. Guideway oil is usually composed of base oil mineral oil and part of sulfur, phosphorus anti-wear agent, cutting fluid, and in the cycle process contact with guideway oil to produce part of the oil-water mixture, that is, sludge.

Oil is lighter than water, oil absorbs most of the alkali and anti-rust components in the cutting fluid, and the role of water makes the guide rail very easy to be oxidized and rusted.

This is not the main reason for rail rust, the main reason is that the anti-wear agent such as sulfur and phosphorus in rail oil is hydrolyzed under the action of the main components of cutting fluid water, and these components of sulfur and phosphorus are seriously corroded to steel components, which is an important reason for rail rust

Tel: 0757-88583990

Email: 574803257@qq.com

Add: No.5 Xingwang Road, Lianxing Wangbian Industrial Zone, Luo Village, Shishan Town, Nanhai District, Foshan City